RUNNING TRACK Construction, DESIGN AND INSTALLATION

During our initial consultation, we’ll help you to design a system that meets your requirements based on the various track options that we have available. We will then arrange a timetable for the installation itself, fitting all of our activity around your organisation’s schedule to minimise the potential for disruption.

ATHLETICS TRACK RESURFACING

If at any stage your tracks require any cleaning, resurfacing or general maintenance, our team will be more than happy to help. As well as maintaining tracks that we’ve installed for our existing partners, we also offer a standalone resurfacing package that’s available to new clients.

WHO WE WORK WITH

Our running track installation services have helped many different types of organisations in the world of athletics, from local training facilities through to elite track and field clubs across the UK. We’ve also worked with some of the country’s top educational institutions.

EXCEEDING OUR CLIENTS’ EXPECTATIONS, EVERY TIME.

- Durham University

- Yarborough Leisure Centre

- The Watershed, Kilkenny

- Homerton College, Cambridge and St. Mary’s School

TRACK AND FIELD SURFACES FOR EVERY EVENT

Having worked on a wide variety of projects, SIS Pitches can provide a combination of athletics tracks surfaces, including:

- All-weather surfaces

- Synthetic polymeric tracks

- 100m sprint straights

- 400m running surfaces

- Type 3 and Type 4 MUGAs

- Long jump and triple jump runways

- Pole vault run-ups and landing areas

- Javelin runways

HIGH-QUALITY SURFACES, installed by experts

We are pleased to offer a variety of running tracks to our clients. The type of track you choose may depend on your facility, budget and usage levels. If you’re unsure, our team can help you to decide whether a porous, sandwich or solid system would be most appropriate. The sections below outline the differences between these types of running track surfaces.

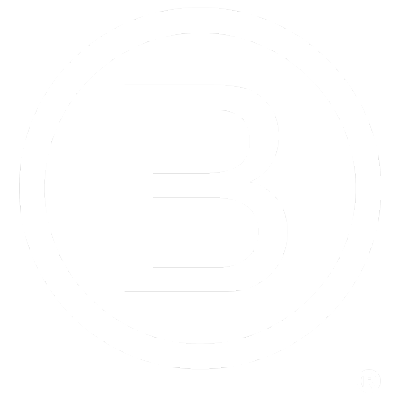

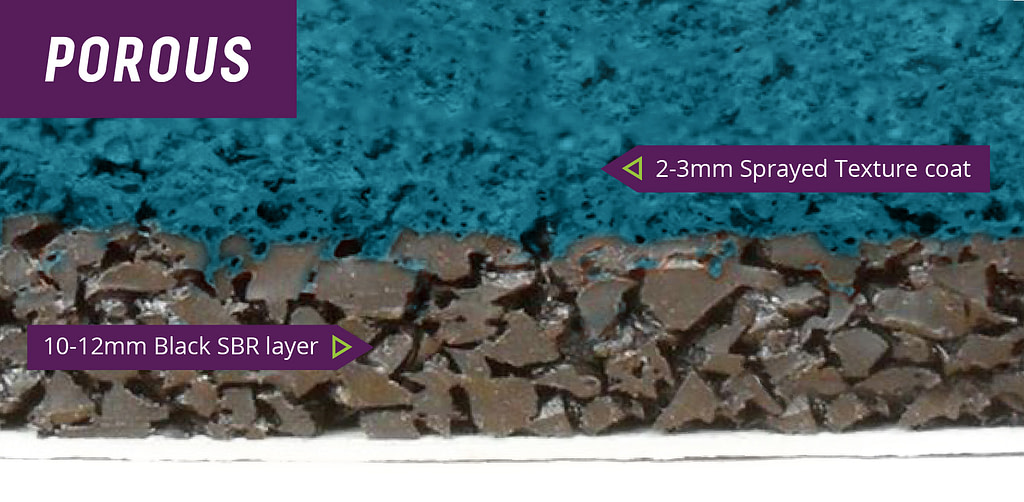

POROUS TRACKS

The most common synthetic track surface in the UK is a porous system. Porous tracks offer a cost-effective solution for facility providers who want to install a track facility for training and low-level local competitions – the softer surface of a porous surface makes it an ideal solution for schools and community athletics clubs.

The system consists of two layers: a base made up of black rubber granules bound in polyurethane resin, and a spray finish of coloured granules and pigmented polyurethane.

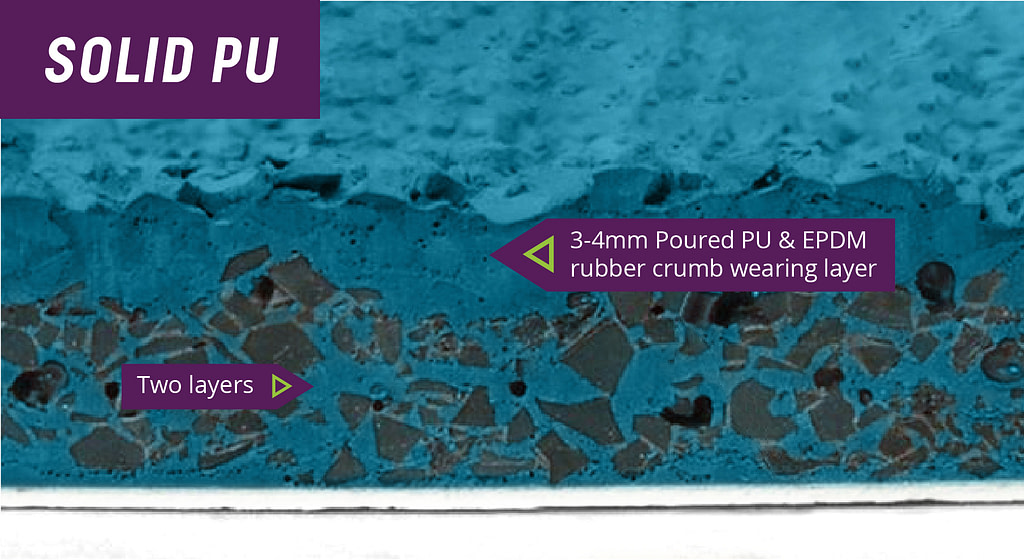

NON-POROUS SOLID SYSTEMS

Non-porous “solid” systems are designed for high-level competition and continuous use, offering a harder surface than other types of athletics tracks (as a result, this type of track is typically preferred by elite-level athletes).

Solid systems have a non-porous full-depth construction comprising two layers: a base polyurethane flood coat layer with rubber granules, and a final flood layer of polyurethane topped with a rubber surface dressing.

As this type of surface is impermeable to water it relies on a fall in the track to a perimeter drain to keep the running surface free of surface water. This method of track construction produces excellent finish levels and is recognised as a first-class surface suitable for international standard athletics.

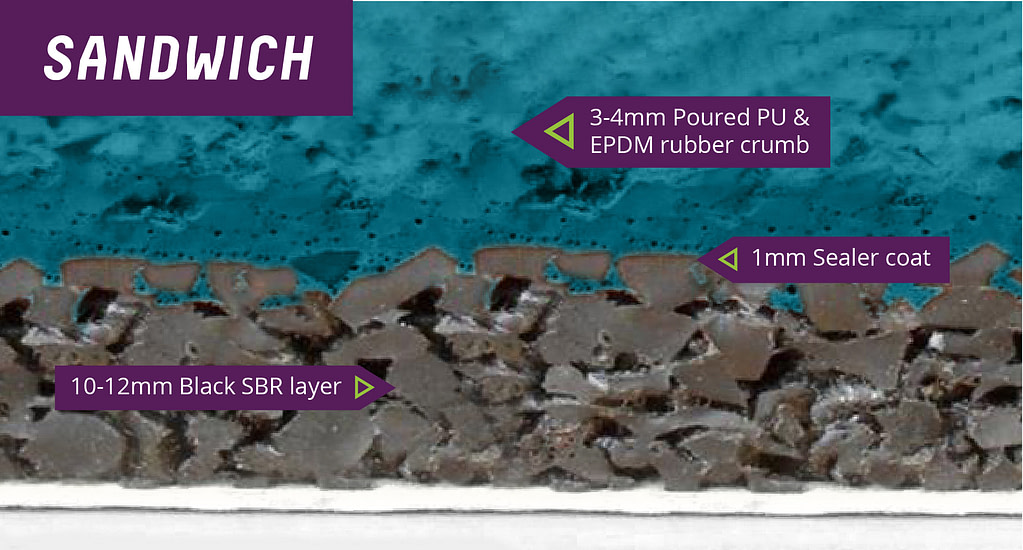

NON-POROUS “HYBRID” OR “SANDWICH” SYSTEMS

Often referred to as “hybrid” or “sandwich” systems, this type of track provides a non-porous elite-level surface at a competitive price. This surface is constructed in two layers: a base layer of black rubber granules with a polyurethane resin and flood coat, combined with a rubber surface dressing.

These tracks require a fall in the track to a perimeter drain, which keeps the running surface free of surface water and improves performance. Hybrid systems are also much more durable than porous tracks, requiring less maintenance and reducing the need for repair work.

Take a look at some of our running track installation projects in the image gallery below to get a feel for the quality and variety of the work we do.